-40%

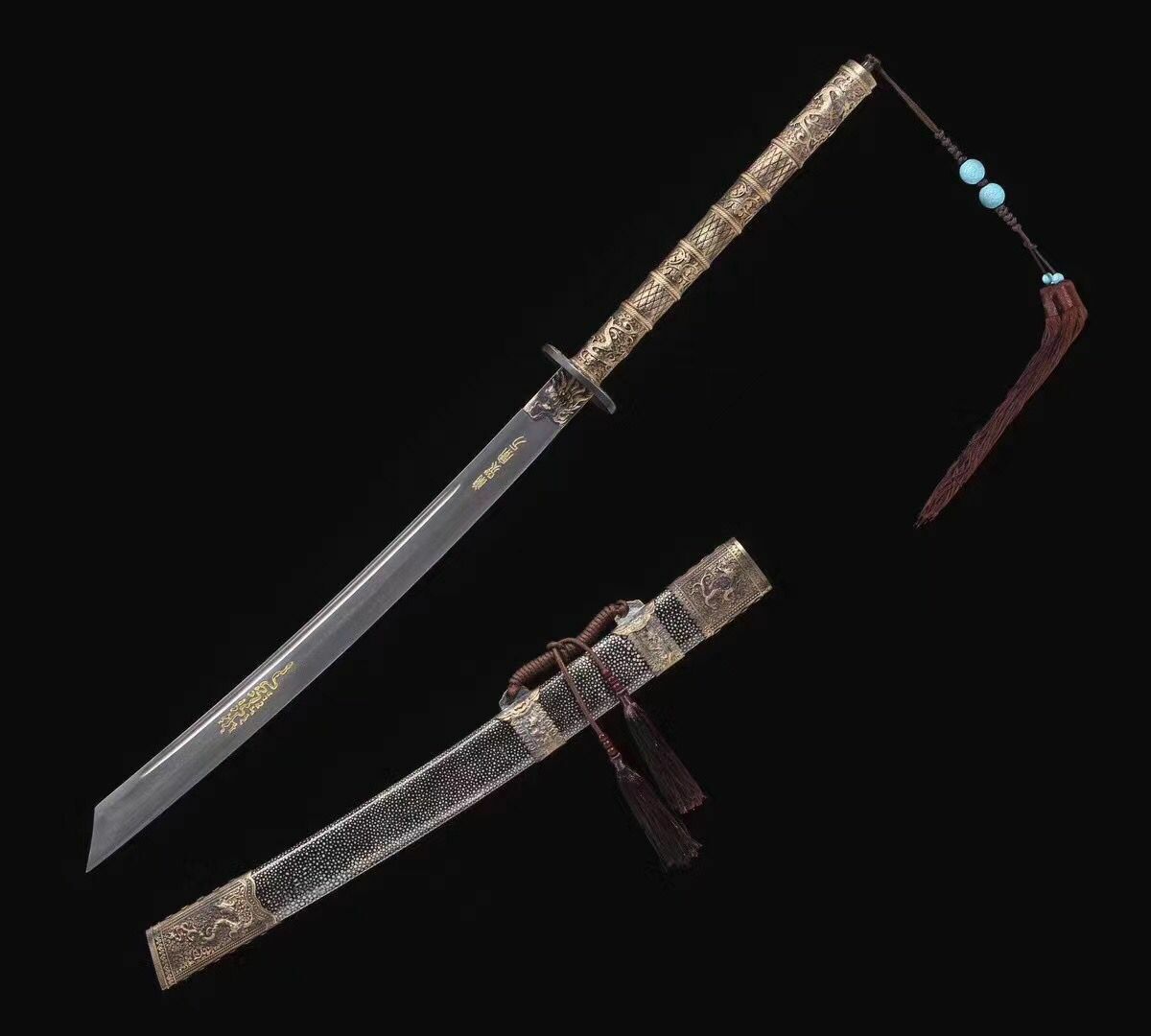

Tang Dynasty Dao Folded Steel Chinese Sword Katakirihadukuri Blade Rosewood

$ 62.83

- Description

- Size Guide

Description

Store categorySign Up Now !

You may also like

Tang Dynasty Dao Folded Steel Chinese Sword Katakirihadukuri Blade Rosewood

Product Description

Dao

are single-edged

Chinese swords

, primarily used for slashing and chopping. The most common form is also known as the Chinese sabre, although those with wider blades are sometimes referred to as Chinese broadswords.

During the

Tang Dynasty

, dao were exported to both Korea and Japan, influencing the swordsmithing of both nations. The blades of Tang era dao are reminiscent of the Japanese chokuto. As in the preceding dynasties, Tang dynasty dao were straight along the entire length of the blade. Single-handed peidao ("belt dao") were the most common sidearm in the Tang dynasty. These were also known as hengdao ("horizontal dao" or "cross dao") in the preceding Sui dynasty. Two-handed changdao ("long dao") or modao were also used in the Tang, with some units specializing in their use.

GENERAL DATA

OVERALL LENGTH:

104 cm / 41''

BLADE LENGTH:

70 cm / 27.6''

TSUKA LENGTH:

26 cm / 10.3''

BLADE WIDTH:

3.2 cm / 1.26''

BLADE THICKNESS:

0.7 cm / 0.28

BLADE HRC:

55

BLADE CRAFT

BLADE CRAFT:

folded forged by 11 times(2048 layers), water quenching

BLADE MATERIAL:

carbon steel

BLADE SHAPE:

Katakirihadukuri

HAMON:

natural riffle hamon, caused by folding process

BO-HI:

NO

SHARPNESS:

★★★★☆

MIRROR EFFECT:

★★★☆☆

MOUNTINGS

HANDLE:

rosewood(huali wood)

SCABBARD:

rosewood(huali wood)

OTHER FITTINGS:

alloy

+ synthetic silk

PACKAGE

1 sword with scabbard

1 black cotton bag

NOTICE

Sword display holder(stand) is not included

Manual measurement error range 1-2 cm

Folded Steel

This means that the carbon steel is folded by 11 times to produce 2048 layers. The higher quantity of layers provides more unique and mystical hada patterns, which defines and displays the craftsman’s experience and knowledge of traditional metallurgy passed down from generation to generation. Only the utmost skilled bladesmiths (Toushyo) and polishers (Togi-shi) can bring out the beauty and life from the Shinsakuto live blade. During the forging process, all of the slags and impurities of the steel are burned off and folded forged to an uncompromised strength with an sharp cutting edge. The final carbon content is 1% and the hardness is an impressive HRC 55°on the Rockwell Scale. This high quality blade can easily cut through tatami straw mats or bamboo for Tameshigiri or Batto-do use.

ENGRAVING SERVICE

HOW TO DISASSEMBLE A JP SWORD

SWORD MAKING PROCESSES

DELIVERY DETAILS

PAYMENT

ENGRAVING SERVICE

It is

free

for engraving English words,Chinese characters and Japanese Kanji.

You need pay

additional

for engraving patterns (dragon, lion, etc.) or other logos.

HOW TO DISASSEMBLE A JP SWORD

SWORD MAKING PROCESSES

Forming

Swords can be shaped by a variety of metalworking techniques.The primary techniques are forging and stock removal.

Forging uses heat to bring the material to a malleable state. The material is then hammered to shape, typically using hammer and anvil together with specialized set and fuller tools depending on the particular technique.

Stock removal shapes the sword from prepared stock that is larger in all dimensions than the finished sword by filing, grinding and cutting.

Quenching

After the blade has been shaped, the sword would be quenched. We quench our swords in either water or oil. Water quenching produces a tougher edge which can also be hardened further more using clay. Blades quenched in oil are still considerably hardened and do have superior flexibility compared to a water quenched blade.

The more rapidly a blade cools down, the harder it becomes. Thus, when a hot blade enters the water, the water also gains heat and the blade will cool more gradually. Therefore, the first part of the blade that enters the water will be the hardest. Therefore, the technique of quenching was also very important. If a blade has any flaws from forging (air bubbles, ash), it will break immediately during the quenching process.

Tempering

After quenching, the sword will be quite tough and brittle, with little flexibility. To overcome this, the blade would undergo a tempering process. The blade would be reheated to a certain temperature degree then allowed to cool naturally. The blade would be slightly less tough afterward but have a greater degree of flexibility – the art would be to perfectly balance the blade for toughness, sharpness and flexibility.

Modifying Shape

Finishing

Finishing encompasses polishing, decorating, and crafting and assembling the hilt, guard and sheath.

The swordsmith would be most concerned with the state of the blade itself and possibly decorating the blade and preparing the guards and pommel. Other artisans would likely be involved in the work of fashioning the hilt, sheath and other furniture; and in any fine decoration.

Polishing

When the rough blade is completed, the swordsmith turns the blade over to a polisher, whose job it is to refine the shape of a blade and improve its aesthetic value. The polishing process almost always takes longer than even crafting, and a good polish can greatly improve the beauty of a blade, while a bad one can ruin the best of blades. Early polishers used three types of stone, whereas a modern polisher generally uses seven.On high quality blades, only the back of the blade and the adjacent sides, are polished to a mirror-like surface. To bring out the grain and hamon, the center portion of the blade, and the edge are usually given a matte finish. Microscopic scratches in the surface vary, depending on hardness. Smaller but more numerous scratches in the harder areas reflect light differently from the deeper, longer scratches in the softer areas. The harder metal appears more matte than the softer, and the manner in which it scatters light is less affected by the direction of the lighting.

After the blade is finished it is passed on to a mountings-maker for fashioning the hilt, sheath and other mountings.

DELIVERY DETAILS

International Buyers – Please Note:

a) Import duties, taxes and charges are not included in the item price or shipping charges. These charges are the buyer’s responsibility.

b) Please check with your country’s customs office to determine what these additional costs will be prior to bidding/buying.

The shipment will be prepared and get shipment as soon as possible when you place the order. The shipping time is different according to the different area.

US:

10-15 days

AU:

8-12 days

Ca:

10-15 days

Others:

25-60 days

It is international shipment, so there are many factors influenced, please let us know if there is any question, we will try our best to make things right for you.

PAYMENT

Only paypal accepted. Paypal is convenient and safe for both of us.

If there is any problem with the payment,you can contact with us at any time.

Feedback